Testing our terminals

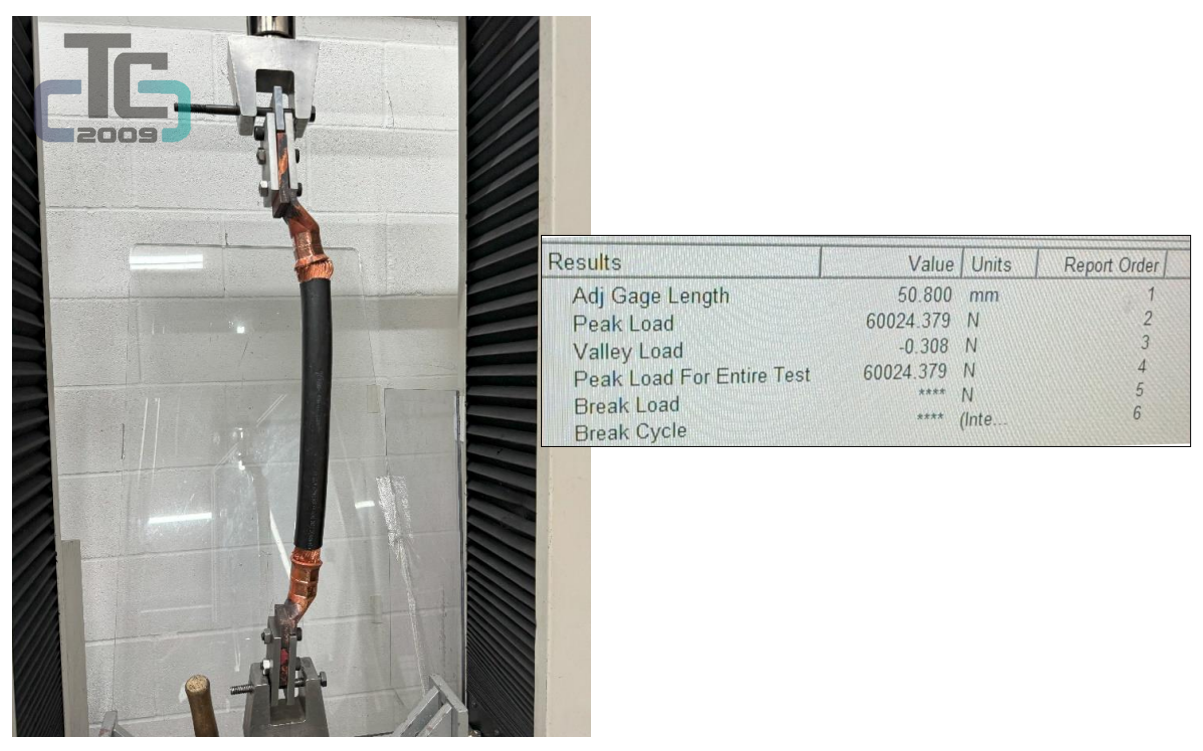

One of our customers recently asked us to carry out pull-testing on one of our products. We assembled this custom-made cable with heavy duty 630mm2 brazed terminals. Our engineering team designed and produced this cable to meet the specific needs of one of our valued customers. The results of the pull test were impressive, demonstrating the high quality and reliability of our products.

We have pull-testing facilities for terminals up to 400mm2, however this exceeded even our capabilities. The testing was therefore conducted by an independent testing centre, and the cable performed exceptionally well. It withstood a peak load of nearly 4 metric tonnes for 60 seconds without breaking. Even under more extreme conditions, the cable held up to a peak load of over 6 metric tonnes. There is a perception that brazed palms suffer from an innate weakness. This testing demonstrates that brazed palms are in fact incredibly strong and reliable.

Manufacturing our terminals

We manufactured the terminals using our proprietary brazing process. They were crimped using a Cembre CPU1131-C hydraulic foot pump and head with AU520 – 630 Crimp Dies. Whilst we are extremely proud of our range of Stanley Dubuis crimping tools, these test results demonstrate that our terminals provide a strong connection even when using competitor tooling. The tested cable assemblies comply with the BS EN IEC 61238-1-1:2019 CLASS2 standard, and as demonstrated by this pull-testing scenario they exceed it by far.

We are proud to say that our skilled engineering team has once again delivered a product that not only satisfies the needs of our valued customers, but also surpasses their expectations. Our products are the result of careful planning, rigorous testing, and innovative design, and reflect our commitment to excellence and quality.